- Rim forming is technology core

- The shape of wheel is looks like lying “H”.

The center disk receives the load and shock as a vertical piller and rim is a lateral piller.

The disk is in out of center depending on inset in the almost case.

The points of rim further distance from center disk receive more load and shock.

From this point of view, it is easy to understand how rim strength is important.

Actually, from the extreme condition test in racing, the most of damage is in rim part.

The thick rim can incraese the strength easily but weight also and it spoils the performance of car.

The lightness and strength, they are in invers position and the accurate intensity calculation, fine design and the technology innovation are necessary to balance up them.

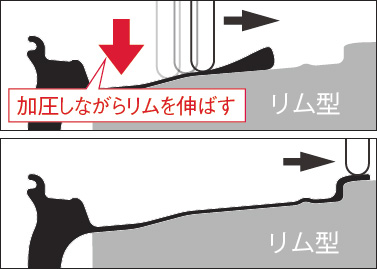

FORGED, HTM (Heat Treatment Manufacture), FFT and FFT-R technologies are the core and improve the rim performance.

These rim forming technologies are selected and utilized in each 1-PIECE, 2-PIECE and 3-PIECE wheel. ※FFT(Flow Forming Technology)