- The best design for each vehicle

-

All of Tanabe suspension is designed for each vehicle specially based on the car character.

The first activity of Tanabe SUSTEC R&D starts on the analysis of original suspension. Through deep analysing, trial piece designed exclusively is installed to the car and thoroughly inspected the fitment, height, contact, noise etc.

As inspected on car actually, the performance and fitment are perfect.

The first activity of Tanabe SUSTEC R&D starts on the analysis of original suspension. Through deep analysing, trial piece designed exclusively is installed to the car and thoroughly inspected the fitment, height, contact, noise etc.

As inspected on car actually, the performance and fitment are perfect.

- Testing run with user’s perspective

-

All of trial piece samples are installed on car and tested the riding comfortability, steering-feel, stability and so on. In case result is not perfect, we reconsiders the setting until making the perfect result.

Our testing run does not need any special course. Public roads are the best to test from user’s perspective because they includes all situations that the user can experience in his daily driving.

Our testing run does not need any special course. Public roads are the best to test from user’s perspective because they includes all situations that the user can experience in his daily driving.

Our material that is done RF induction heating treatment is very special spring steel. And our 210Technology can gain 2,100N/

Our material that is done RF induction heating treatment is very special spring steel. And our 210Technology can gain 2,100N/ The advantage of spring made by cold forming is high strength, no setting in fatigue and gentle initial rebound. The ride feeling is more stable without losing comfortability. Our spring cross section is rough but this is the evidence for cold forming by high power machine that can form and cut more than 14mm diameter material.

The advantage of spring made by cold forming is high strength, no setting in fatigue and gentle initial rebound. The ride feeling is more stable without losing comfortability. Our spring cross section is rough but this is the evidence for cold forming by high power machine that can form and cut more than 14mm diameter material.

5cm stroke x 1,000,000 times (whole 2 to 3days) for coil spring.

In this test, metal fatigue, deformation and rate change are checked.

As same as coil spring test, the damper is also checked by stroke test for case temperature, oil leaking, seal condition, rod deformation and damping force.

5cm stroke x 1,000,000 times (whole 2 to 3days) for coil spring.

In this test, metal fatigue, deformation and rate change are checked.

As same as coil spring test, the damper is also checked by stroke test for case temperature, oil leaking, seal condition, rod deformation and damping force.

Measures for rust

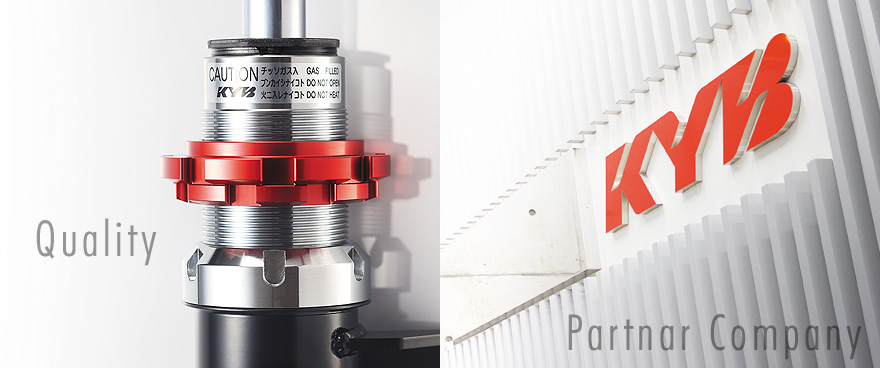

Measures for rust Our SUSTEC PRO series dampers are developped and manufactured in the same factory of Lexus damper.

Needless to say their technology and quality, their sincere attitude for manufacturing is also one of reason that we decided to have partnership.

Our SUSTEC PRO series dampers are developped and manufactured in the same factory of Lexus damper.

Needless to say their technology and quality, their sincere attitude for manufacturing is also one of reason that we decided to have partnership.